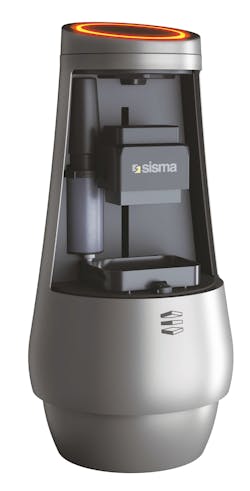

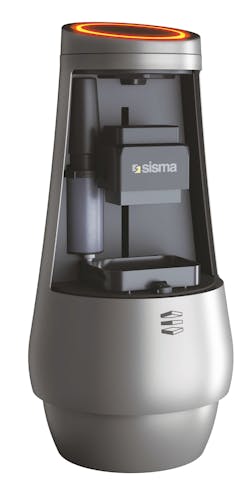

What’s new? The printers, which feature Sisma’s new Zero Tilting Technology (ZTT) and Smart Building Platform (SBP). Both technologies are patent-pending.

Benefits Ease of use and precision. The printers’ SBP is fully automatic, removing the need for manual calibration or intervention, as well as eliminating the possibility for operator-caused damage. The machines automatically recognize resin cartridges and cleanly load and unload resin. Also, with Sisma’s ZTT, the machines can produce parts without the distortion that can be caused by other DLP printers. The resin vats of other DLP printers move as the printers form each layer; this movement can cause the resin between layers to be compressed, creating mechanical stress on the part — a problem that’s exacerbated with especially tall parts. With Sisma’s printers, however, the vat does not move, guaranteeing the same degree of precision, from the first layer to the last. In addition, because they are made of polytetrafluoroethylene, an inert material, Sisma’s resin vats protect the integrity of the part.

Sisma USA Inc., Pine Brook, N.J., 973-214-9970, www.sisma.com