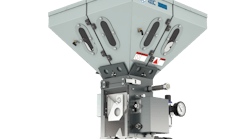

1BLOW 2L This compact stretch-blow molding unit from 1Blow incorporates the principles of high-volume bottle production of a rotary machine with low-cavitation tooling.

WHAT'S NEW? A proprietary design that allows nine of the unit's 11 motions to operate in a rotary fashion without the expensive, complex rotary union component that's central to a traditional full rotary unit. A new technology kit developed in 2014 delivers preferential and off-set neck heating.

BENEFITS The production of bottles up to 2.5 liters in two cavities at rates up to 2,000 bottles per cavity per hour. A unit capable of producing 4,000 bottles per hour will be demonstrated at NPE. Bottles with a maximum height of 352mm, diameter of 115mm and neck diameter up to 38mm can be molded in standard, oval, hot-fill and oriented neck styles.

1Blow, Paris, France, 678-417-0050, www.1blow.com