Offering convenience and user-friendliness, technologies displayed at the International Plastic Fair in October in Tokyo included an updated mold temperature controller and fully assembled hot-runner system. In promoting their products, the manufacturers stressed their ease of use.

SINGLE UPDATES SCT MOLD TEMPERATURE CONTROLLER

Single Temperiertechnik GmbH, Hochdorf, Germany, updated its SCT series mold-temperature controller to make it more user-friendly, said Roberto Pace, VP of sales and marketing for Asia Pacific.

The SCT controller — which was first introduced at the K2013 in Germany — has been updated with a 7-inch color touch screen. It has menu-driven icons and provides easy-to-read feedback. Compared to the old version, which featured buttons used to input settings and a display screen with a hard-to-read font, the latest iteration simplifies programming and navigation.

The company's SCT controller is designed for closed- or open-loop mold temperature control. It is offered in two versions: the SCT standard and the SCT professional. Additional digital interfaces allow it to be integrated with a manufacturing execution system (MES) or plantwide monitoring/control system, Pace said. The controller can communicate with systems using different digital interfaces simultaneously.

In addition, the unit features new icons that help with mold maintenance. "The controller provides more detail. The unit can prompt the user regarding maintenance," Pace said. It performs more comprehensive self-diagnostics and can store process data, such as mold temperatures and flow rates. The controller lacked the capacity to store such data previously, he said.

Users can arrange the icons and screens that display operating parameters and process views to their liking. The unit provides troubleshooting tips and instruction in 16 languages. In addition to providing detailed operation, warning and alarm messages and parameter designations, the unit also can receive and retrieve text messages.

The higher-end SCT professional model has several additional features. They include a pressure sensor, pressure display and function for setting and monitoring pressure parameters.

The professional model also includes an analog interface to communicate set point and actual values via electric or voltage signal, analog heating and cooling outputs and control and parameter options for handling special temperature-control processes and systems, Pace said.

HASCO LAUNCHES FULLY ASSEMBLED AND WIRED HOT-RUNNER SYSTEM

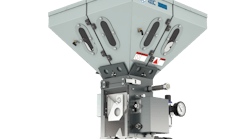

Hasco offers a new, fully assembled and wired hot-runner system as part of its range of ready-to-install systems and hot halves.

The H4016 wired hot-runner system uses Hasco's new Vario Shot H6500 high-performance hot-runner nozzle and can be easily and securely mounted or removed from the mold. Connector cables for the individual nozzles and the hot runner pass through individually configured cable ducts to the connection box where they are wired according to customer specifications. Hence, a mold maker or molder does not have to undertake the wiring.

Hasco's assembly guarantees tight connections between the hot-runner manifold and screw-in nozzle, eliminating the risk of leaks.

Hasco said that specially tailored screw-on melt chambers make mounting in the mold even more secure.

Mikell Knights, senior staff reporter

For more information:

Hasco America Inc.,Fletcher, N.C., 828-650-2600, www.hasco.com

Single Temperature Controls Inc.,Charlotte, N.C., 704-504-4800, www.single-temp.com