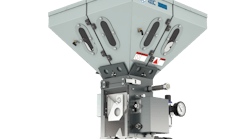

Actuation Plate for Valve-Gate Systems Thermoplay's compact unit allows mold cavities to be closer, compared to the use of individual actuators for each nozzle. This unit allows each needle's length to be mechanically adjusted individually, and individual cavities can be locked open or closed. The bottom plate of the mold provides access for adjustments. Thermoplay, based in Italy, is represented in the U.S. by Synventive Molding Solutions. Both firms are part of the Barnes Group.

What's new? Opposed, single-acting actuation pistons, which allow more reliable movement of the actuation plate while avoiding any blocking event. This is the first time it is being shown in the U.S.

Benefits Individual needle and cavity adjustments can be done externally without disassembling any mold components. Actuation can be pneumatic, hydraulic or electric. Also, the electric actuation plate requires minimal maintenance.

Synventive Molding Solutions Inc., Peabody, Mass., 978-750-8065, www.synventive.com