Visitors to NPE2018 will have the opportunity to peruse new and upgraded hot runners. Both Mastip and Mold-Masters are launching new drop-in systems. And, Vulcan Plastic Machinery, which was established in 2015 as a hot-runner company called Vulcan Hot Runner Controllers, continues to expand its offerings.

MASTIP

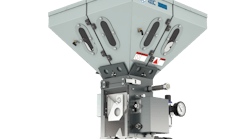

The VeriShot Single Valve Gate (SVG) system from Mastip is ideal for parts requiring precise gate finishes, fast flow rates and dimensional accuracy.

The preassembled valve-gate system incorporates several Mastip features, including the company's high-performance X Range gate geometry, tips and nuts. It is offered with Mastip's TX19 and TX27 FlowLoc threaded leak-proof nozzles that screw directly into the lower manifold for secure operation. It incorporates an advanced heating technology that provides exceptional thermal control and allows it to handle a wide range of engineering and commodity polymers. Valve-pin actuation is pneumatically driven, the company said.

It has a compact, ring-shaped design that greatly reduces mold height requirements. The device ensures precise alignment between mold and machine platens.

When used in conjunction with other patent-pending Mastip technologies — including high-temperature seals and an adjustable valve pin, the VeriShot SVG provides leak-free operation and low mold-filling stress that reduces molding pressure, for superior part quality and consistency.

Mastip also developed the Nexus, a new pre-assembled, prewired system that can be installed in a mold easily. Featuring fully customizable frames, electrical connections and tip and nut options, it is suited for manufacturing small to medium automotive parts, medium to large appliance parts and large electrical parts. Mastip's FlowLoc 16 series, 19 series and 27 series thermal-gate nozzles or valve-gate assemblies can be selected for use with the system.

MOLD-MASTERS UPDATES NOZZLE AND SIDE-GATING TECHNOLOGIES

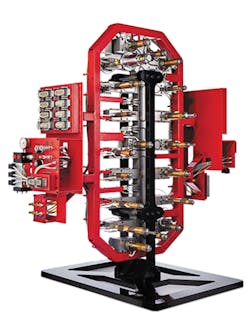

Mold-Masters has expanded the capabilities and applications of its Fusion Series G2 hot-runner system with two new nozzles.

The Fusion Series G2 is a drop-in hot-runner system that comes wired and assembled and is targeted at markets such as automotive and appliance manufacturing.

The system has a single point of connection to the injection press, which eases installation while promoting faster startup, operation and maintenance. It monitors the position of the valve pin and controls its opening speed to improve the surface of the part.

The new F3000 nozzle handles shot sizes of less than 15 grams, and is used to produce small, under-the-hood and technical automotive components. The new nozzle can also be used in non-automotive applications such as consumer goods and packaging.

With Mold-Masters' new F8000 nozzle, using diameters as large as 28mm, the hot-runner system can handle shot sizes of up to 5,000 grams; the F8000's maximum length is greater than 3 feet. The company developed it to meet the processing requirements of common large white goods and large automotive components, such as fascias, instrument panels and door panels.

The new nozzles join the F4000, F5000, F6000 and F7000 nozzles in the series.

Mold-Masters also has updated its Melt-Cube side-gating hot runner for molds having up to eight cavities. Melt-Cube provides excellent vestige control, low pressure drop and precise rheological balance from cavity to cavity, the company said. Direct side gating eliminates the production of wasteful sub-runners while offering a higher pitch density than a circular system, resulting in greater production output.

The company simplified the design to make the unit easier to maintain and service. For example, the tips of each gate are clamped by a single bolt in sets of two, which reduces assembly and disassembly times by up to 85 percent. The design allows for manifolds to be easily accessed.

Melt-Cube incorporates the company's brazed heater technology that delivers a precise thermal profile. It is suited to the production of deep-draw medical parts such as pipette tips, syringe barrels, needle shields and parts where only side gating is permitted.

VULCAN UPDATES HOT-RUNNER CONTROLLER

Vulcan last year changed its name to reflect its expanding portfolio of wares. The company, which began with a focus on making no-frills, low-cost hot-runner temperature controllers that also are robust and perform well, now offers auxiliary equipment, such as portable resin dryers, portable chillers and mold temperature controllers, as well as components for primary machinery, President David Crain said.

At NPE2018, it will launch additional capabilities for its YK-D hot-runner controller line. A standard version of the YK-D, introduced in 2016 and commonly offered with one to 48 zones of heating, is now available with up to 72 zones, Crain said.

Users can select a one- or two-zone controller for use with a one- or two-zone application or for use with a hot sprue bushing, Crain said. The YK-D is also offered with four, six, eight, 12, 24, 36, 48 and 72 zones as part of a mainframe package that includes the modules, cables and mainframe housing.

At the customer's request, Vulcan can design a model with up to 96 zones.

Features of the YK-D line include the ability to set temperatures from 100 degrees Fahrenheit to 1,000 degrees Fahrenheit, with a sampling rate of 0.1 second and actual operating temperature that is accurate to plus or minus 0.5 degree Fahrenheit of setpoint. Each temperature zone uses a 15-amp fuse. Users can operate the unit in automatic, manual or standby control modes and set alarms for high or low temperatures. Other basic features include soft start. The YK-D can be used with any hot-runner system, Crain said.

Mikell Knights, senior staff reporter

Contact:

Mastip Inc., Slinger, Wis., 262-644-9400, www.mastip.com

Mold-Masters Ltd.,

Georgetown, Ontario, 905-877-0185,www.milacron.com

Vulcan Plastic Machinery,

El Paso, Texas, 915-730-6640,www.vulcanplasticmachinery.com