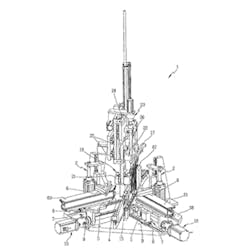

Toss GmbH & Co. KG, Alten-Buseck, Germany, has applied for a patent for a device to weld plastic films using hot gas. The device would use an electrical current flowing through a tubular body to heat the gas, and an array of gas outlet openings to blow the gas onto plastic film.

Toss says the device would allow for even heating of the gas, as well as even distribution of the gas across the surface of the plastic film to be welded. The company also claims it could precisely adjust the temperature of the emerging hot gas.

This would overcome common problems cited with existing devices, which cannot consistently regulate the heat of the gas exiting their outlets. Therefore, some outlets may expel gas that is not hot enough to successfully weld plastic film, and others may expel gas that can result in uncontrolled melting of plastic film.

The main tubular body of the applicant device would form a pressure reservoir to promote uniform flow and even temperature of the emerging gas. In some embodiments, the welder would have branching tubular bodies with substantially identical shapes, again to maintain a consistent temperature for the hot gas exiting the outlets.

In a preferred modification, the device employs modules, with each module having a main tubular body and at least one branching tubular body with electrical current flowing through it. This would allow flexibility for users to adjust either the welder's speed or welding temperature.

Patent application 20180169959; published June 21

Injection mold. A maker of automotive interior parts has proposed a mold designed with air canals for manufacturing parts with unblemished, textured, leather-like surfaces.

In its patent application, Toyota Boshoku Kabushiki Kaisha, Aichi, Japan, notes that, in typical mold setups, the forming surface of a mold can rub against the embossed surface of a part, resulting in damage to the design. To counter this problem, it proposes a method of creating an air gap between the part's design surface and the forming surface. Molds employing this method must include air canals, and the process also makes use of external blowers.

Patent application 20180178464; published June 28

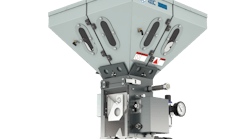

Plastic joining. An Italian maker of equipment for window- and door-frame manufacturers has invented a device that simultaneously welds plastic profiles and removes beads formed by the melting plastic.

The device can encompass both a welder, as well as other tools, such as an apparatus for milling, that can smooth the surfaces of parts to improve their appearance.

Graf Synergy Srl, of Nonantola, states in its patent that the device will eliminate the need for post-welding machining of joined PVC parts.

Patent 9,993,969; issued June 12

Injector. Inglass SpA, San Polo di Piave, Italy, received a patent for an injector for injection molding that features a nozzle and a pin-shaped valve. The valve can be adjusted to change its annular passage depending on the viscosity of the material being processed. The valve is actuated by an electronically controlled electric motor that provides more accurate control of the flow of the resin through the injector. This improved accuracy results in better-quality molded parts, the patent states.

Patent 9,999,999; issued June 19

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received apatent? Contact [email protected]