Companies that serve pipe and tubing manufacturers recently have rolled out new devices for rolling up plastic products.

At NPE2018, FB Balzanelli went big, touting a huge coiler for pipe, while RDN Manufacturing and C.W. Brabender offered winders for smaller batches and products. FB Balzanelli touts its new machine's size; the other companies promote their products' control capabilities and modularity.

FB BALZANELLI

FB Balzanelli's prodigious new FB ML7 5200 coiler can accommodate large-bore pipes made from PE with diameters as wide as 10 inches.

The fully automatic machine can secure the pipe to the reel, coil it, execute intermediate and final strapping and offload the coil without operator supervision. It can accommodate coils with outer diameters ranging up to 17 feet and widths of up to 8 feet. Ten-inch-diameter pipe that's been coiled by the machine can stretch out as far as 1,500 feet, and the full coil can weigh as much as 11 tons.

According to the company, the resulting coils of pipe are up to 10 times longer than standard coils.

With its ability to coil such a large quantity of pipe, the machine is beneficial to both pipe installers and pipe makers. The coiled pipe is much longer than the cords of pipe that are normally shipped, so pipe installers can weld fewer sections together, making installation faster and less expensive. Also, the company pointed out, with fewer weld lines, the pipe is more resilient once it's installed.

Previously, the company's largest coilers could handle pipes with diameters as large as 8 inches.

Designed for manufacturers serving the petroleum industry, a coiler was recently installed at a site in Australia.

RDN MANUFACTURING

Suited for use by manufacturers in the medical and automotive industries, RDN's new servo-controlled roll winders produce a near-perfect, level roll. According to the company, the products feature an easy-to-use interface that simplifies setup.

"The winder is for all flexible material," President Dave Wille said. "It would be perfect for 3-D filament."

The made-to-order winders have a footprint of about 30 inches by 30 inches and can handle pipes and filament made at speeds of up to 250 feet per minute. To begin, operators enter the outer diameter specs of the tube they plan to wind and an estimated line speed. Once operations begin, the winder can accommodate any line speed that's within 25 percent of the estimate.

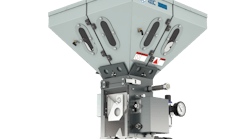

C.W. BRABENDER

Designed for R&D work, C.W. Brabender's new winder also can be used for small-diameter hose production, said Paul Nardone, sales manager for the company's North American chemical division. It has a maximum haul-off speed of about 66 feet per minute and can accommodate filament diameters ranging from 0.5mm to 4mm and hose diameters of 0.5mm to 12mm.

It features a digital display screen and three separate drives and controls.

The winder's modular pinch puller and belt puller are mounted on a rack in front of it and can be exchanged easily mechanically and electrically, Nardone said. An oscillating unit ensures even and steady winding of the extrudate. The tension between the oscillating unit and nip rolls is adjustable.

The winder has a footprint of about 2.3 feet by 3.9 feet and stands about 5.2 feet tall. It can accommodate coils weighing a maximum of 264 pounds.

Karen Hanna, copy editor

Contact:

C.W. Brabender Instruments Inc., South Hackensack, N.J., 201-343-8425, www.cwbrabender.com

FB Balzanelli USA Inc.,

Plymouth, Mich., 734-455-7752,www.fb-balzanelliusa.com

RDN Manufacturing Co. Inc.,

Bloomingdale, Ill., 630-893-4500,www.rdnmfg.com