Injection mold manufacturer Cavaform International LLC, St. Petersburg, Fla., has patented a melt distribution device that provides greater precision when molding parts, such as medical pipettes, that must be perfectly straight to function optimally.

According to the patent, a common problem when molding long parts is that the resin can cool at different rates in different locations in the mold, causing the part to bend slightly. Typically, the parts bow inward toward the hot side of the tool. Dual-gate systems created to address this problem can have issues with asymmetrical melt delivery.

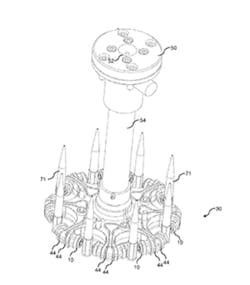

In one embodiment of the device, a melt distributor has an orifice for receiving molten plastic and multiple melt distributor channels, each ending in an injection tip that connects to an injection port in a mold assembly. Because the melt channels are the same size, the melt flows evenly through each of the injection tips and enters the mold assembly at the same time, flow rate and temperature. In another embodiment, the system includes an injection nozzle interface plate that is attached to the press.

The device has a single heating element that is wound around its entire base to evenly heat each of the channels and exit ports. This eliminates thermal variances in the melt that create unequal flow rates and part warping, the patent states. The system also reduces the amount of runner waste.

Patent 10,011,062; issued July 3.

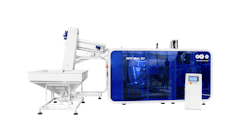

Automation. Krones AG, Neutraubling, Germany, has devised a robot for use with blow molding machinery. Unlike other robots, which handle either mold changes or heating device changes, Krones said some embodiments of its robot can perform both actions — or even multiple tasks across several machines. Because of its versatility, the robot will be more cost-effective than competing setups, Krones claims in its patent.

Though it has only one arm, one version of the robot is equipped with two sets of end-of-arm tooling (EOAT) — one for gripping a mold, the other for heating device changes — that it can swap out autonomously. Alternatively, the changing apparatuses can be attached to opposing sides of the robot, or placed near the robot, either in a stationary position or on a movable device, such as a rail system or cart.

Krones, which makes bottling machines, says the technologies also pertain to manually operated manipulators.

"This way, the existing changing device can remain in use and be better utilized. Furthermore, the operating personnel can be used more efficiently, as just one changing device can change all handling parts preferably completely by itself," the company states in its patent.

Patent 10,000,027; issued June 19

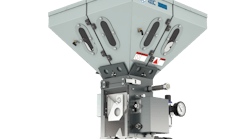

Injection molding. Inglass SpA, San Polo di Piave, Italy, has invented a device that controls the action of an injector's valve pin based on actual process conditions instead of operating parameters.

The device comprises a melt distributor connected to at least one injector that has a valve pin controlled by an electric rotary actuator. The device measures the torque of the electric rotary actuator when the valve pin is moving from a closed position to an open position.

According to the patent, it typically is difficult for an electric rotary actuator to react to actual process conditions such as temperature, viscosity and packing.

"The invention is based on the finding that the torque developed by the electric motor … is a function of the pressure of the plastic material injected into the mold," the patent states. "Through the detected torque value, the control of the electric actuator can, for example, act on the positioning of the valve pin to increase or reduce the flow of plastic material into the mold, or act on its speed, varying it in a suitable manner."

According to the patent, the device is particularly advantageous in sequential injection because it can vary the movements of the multiple valve pins to ensure optimal melt distribution in the mold cavity. It is also useful for molding parts that require a high degree of mechanical and aesthetic quality, such as automotive bumpers.

Patent 9,981,414; issued May 29

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received apatent? Contact [email protected]