The company has introduced its “Zero Cooling” PET container molding technology, which brings a 50 percent increase in productivity and improves container strength by 15 percent.

The company’s ASB-Series four-station blow molding machines now come equipped with the new technology.

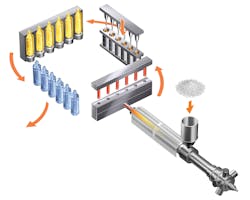

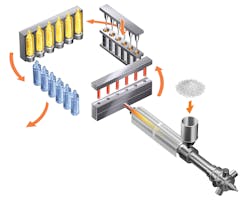

Standard, four-stage, one-step blow molding starts with the injection molding and cooling of a preform. The preform remains above PET’s glass-transition temperature so that it is still flexible as it moves to the second station in the process.

The preform is conditioned in the second station, blow molded in the third station and ejected in the fourth station.

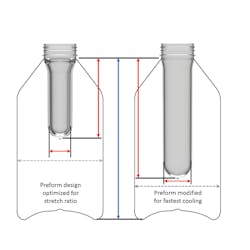

The new process also leads to containers with improved physical properties because smaller, thicker preforms can be used. Such preforms have higher stretch ratios, resulting in excellent material distribution and top-load strength about 15 percent greater than preforms made by standard one-step blow molding, according to the company. In other systems, preforms tend to be longer and thinner to minimize cooling times.

Using smaller, thicker preforms also improves the aesthetics of the product because larger, thinner preforms can be subject to defects in the finished container, such as fish eyes, body ring and orange peel, the company said.

The cooling method also is suited for molding heavy premium cosmetic containers that exhibit no haziness in very short cycle times using standard PET grades, the company said.

Bruce Geiselman, senior staff reporter

Contact:

Nissei ASB Co.

Smyrna, Ga., 404-699-7755,