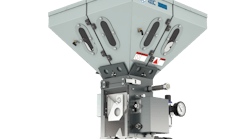

What’s new? An all-new, next-generation laboratory testing system called Gawis 4D. The inspection system, which Agr unveiled at K2019, incorporates optical gauging and proprietary infrared-light spectrometer thickness measurement technology. New features include AutoJob, which provides for automated recognition of key measurements on bottles and preforms, and Industry 4.0 communications protocols. Agr plans to deliver the first Gawis 4D systems in the first quarter of 2020.

Benefits Simplified job setup, an increase in measurement throughput of up to 30 percent and 360-degree imaging. The Gawis 4D system offers comprehensive, precise measurements that can be used to qualify and manage the molds used to manufacture PET, PE and PP containers. Also, by allowing for automated job setup, the AutoJob feature can save operators hundreds of hours of labor over the course of a year.

Agr International Inc., Butler, Pa., 724-482-2163, www.agrintl.com