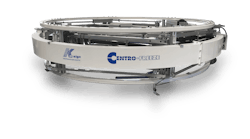

RS-90 Rocheleau Tool & Die's RS series of reciprocating-screw blow molding machines is targeted at HDPE and PP containers. The machines offer fast cycle times and optional parison programming — the ability to electronically control the wall thickness of the parison to create a finished part with consistent material distribution and reduced weight. The RS-90 is a hybrid model that is powered by both variable-frequency-drive electric technology and hydraulics. Two high-torque, high-force rotary actuators generate the clamping force.

What's new? The size. The RS-90 is Rocheleau's largest reciprocating-screw machine, and is especially suited for making containers for industrial and consumer products. Various die head configurations are available to accommodate molds with one to 16 cavities. With its 90mm-diameter extruder, it is capable of throughputs of more than 750 pounds of resin per hour. The RS-90's clamping unit has a 16-inch-tall-by-48-inch-wide usable platen area. It joins RS models with 25mm, 70mm and 80mm extruders. Additionally, the machine can be integrated in-line with the company's new VT-3 deflash automation package, which transfers parts in an upright orientation to a punch station for trimming. The VT-3 is sized specifically for the RS-90 and typically is used to trim scrap from bottles with handles or remove flash around the shoulder.

Benefits Energy efficiency and simple operation due to the hybrid technology. Also, the extra-thick, nickel-plated platens ensure even distribution of the clamping force and minimal deflection.

Rocheleau Tool & Die Co. Inc.,Fitchburg, Mass., 978-345-1723, www.rocheleautool.com