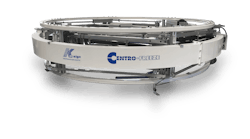

e-motion 120 TL Engel's latest all-electric, tie-bar-less injection molding machine is compact and especially appropriate for making small precision parts for the electronics and medical industries. It is designed to provide optimum access to the mold area and has a clamping unit with encapsulated toggle levers to prevent oil leaks. The press features a high-precision adjustment system for platen parallelism.

What's new? The size. The largest in the e-motion TL series, the 120 model has a clamping force of 135 tons. Engel added the machine to the line to accommodate the trend toward multi-cavity molds. The machine will be available worldwide next month.

Benefits Efficiency. Because it has no tie bars, the comparatively small injection molding machine can run large and bulky molds. Therefore, the required clamping force can be the determining factor in what size machine is used, instead of the size of the mold. This saves money and energy.

Engel Machinery Inc., York, Pa., 717-764-6818, www.engelglobal.com