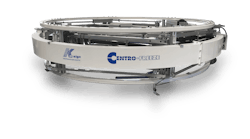

Multi-InspectionCollin’s film-inspection apparatuschecks material composition, melt viscosity and elasticity; and looks for defects, such as dark spots, off-spec color and haze. It can be used in conjunction with a lab extruder for R&D and is especially suited for extrusion facilities that make film with recycled content. In in-line setups, the device is connected to the main production line via a special adapter tip, and a small amount of melt is diverted to be tested by the system.

What’s new? The release of Generation 2. The latest version of the Multi-Inspection includes a new and much more compact die with a melt pump used to create a small film sample; a new camera system with upgraded LED technology; and an upgraded infrared-light detection model for better material analysis.

Benefits All-in-one capabilities to take a variety of measurements. The newest Multi-Inspection boasts improved detection capabilities, new image processing and better and easier access for maintenance. Users can fine-tune their process in real time, without wasting a significant amount of material.

Collin Lab & Pilot Solutions Inc., Tucker, Ga., 678-325-6708, www.collin-solutions.com/en