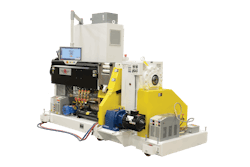

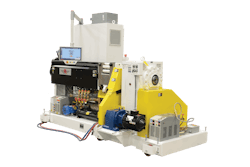

The company began offering the digital controls on the extruders in October, featuring the machines at the International Rubber Expo in Louisville, Ky.

The XC200 Navigator can control one or more extruders in simultaneous operation. Optionally, the HMI can be mounted on a swing arm. It has hard-wired e-stop, start, stop and reset buttons. It offers intuitive visual navigation by touch screen with easy-to-understand icons for controls, status and alarms, along with integrated machine documentation, according to American Kuhne.

The system controls closed-loop barrel PID heating and cooling; clamp and die zone settings; and extruder screw speed. It offers high-pressure shutdown; a high-temperature alarm; heater burnout detection and alarm; and remote diagnostics. It comes with a melt-pressure monitor with dual alarms; soak time and cold-start interlock; a seven-day timer; and a recipe manager. It can track alarm history and extruder parameter trends, as well as real-time I/O diagnostics.

“The XC200 Navigator control system is a state-of-the art option to discrete controls that are still common on many extruders in the segment,” said Brad Sprague, American Kuhne regional sales manager. “One of the biggest advantages to pipe and tubing processors is the instant on-screen access to operation and maintenance I/O and documentation, including remote access via smartphone with our optional TeamViewer application.”

American Kuhne first introduced the XC200 Navigator control system on some of its Ultra extruders in May 2018.

Bruce Geiselman, senior staff reporter

Contact:

American Kuhne York, Pa., 717-848-3755,