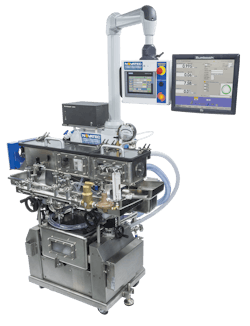

Novatec has entered the medical tubing machinery market with the introduction last month of its Bessemer Rx-SmartMED series of downstream extrusion equipment.

Robert Bessemer, an industry veteran with more than 35 years’ experience, joined Novatec in August as VP of extrusion technology and has been developing the new equipment. The initial offerings include water tanks, vacuum tanks and a puller-cutter designed specifically for medical extrusion.

“Medical microbore is the first area that I am focusing on with Novatec,” Bessemer said. “That’s where you’re making small heart- and brain-catheter-size tubing, say 0.1 [inch] and as small as 0.01 [inch] with multilumens.”

The company’s new water-cooling and vacuum-sizing tanks will be sold in 3-foot, 5-foot and 8-foot lengths.

The Bessemer Rx-SmartMED MVT-series medical vacuum tanks include vacuum, as well as water-seal and air-wipe chambers with 0.5-inch-thick tempered-glass lids.

Novatec’s water and vacuum tanks are designed with unique features to reduce cleaning times and meet the sanitary requirements for medical tubing, Bessemer said. “I’ve been involved with this industry for about 36 years, and, really, water tanks and vacuum tanks first used for medical tubing were the same tanks they used for making industrial tubing or straws,” he said. “To make it a medical tank, in some cases, they just painted it white. They really didn’t put the adequate features in, and the industry has been very slow to adapt.”

Bessemer said he adopted technology from another industry — beverages — for design features that minimize bacterial growth in the new tanks.

“The crazy thing is, a lot of the features we have added, the types of valves, the finish, are the valves they use in the production of wine, beer and dairy products,” he said.

Novatec’s tanks feature tri-clover fittings, which don’t use threads, in place of traditional valves and fittings.

“They are basically like a clamshell clamp to hold the two halves of the fitting together so they can be easily, without a tool, popped apart and washed down,” he said. “I couldn’t get rid of every last thread, but we have tremendously reduced the number of threads that contact your process water.”

Bacteria commonly form in tanks on threaded surfaces that are exposed to process water, and those threaded surfaces are difficult to clean. Despite workers’ efforts to clean threaded fittings, flushing or wiping them down can be ineffective, he said.

In addition to using the special fittings, Novatec builds the tanks out of 304 stainless steel and uses rounded corners and electropolished surfaces on areas that come into contact with process water to reduce biofilm formation and bacterial growth.

“I had seen some of my customers for years buy a relatively inexpensive water tank from whomever, and they would send it out to another house to retrofit it to put on different water filters and water pumps, and they would replumb the whole thing after buying it from a manufacturer,” Bessemer said. “To me, that was unsatisfactory that you couldn’t go out and buy a tank properly designed for manufacturing/processing medical tubing.

“When I came to Novatec, I had the ability to start with a clean slate. The biggest thing with medical tanks was the cleanability of that tank. Where does bacteria form, and what can we do to minimize the formation of bacteria? That is why we are making all these features standard.”

The tank also is designed with a quick flushing and draining system that uses a three-way water valve, Bessemer said. Because regular cleanings are essential, Novatec’s design allows the water pump to drain the system, which can significantly reduce cleaning times. Some other tank designs require workers to swab out and siphon tanks during cleaning.

Novatec also is installing a three-stage water filter on its tanks. The first filter stage captures particles as small as 5 microns, followed by a 2-micron stage and a 0.5-micron stage. A UV light renders germs sterile, and a filter then removes the bacteria.

“The cleanability is probably the biggest feature,” Bessemer said. “Everything was designed for ease of cleaning and washdown.”

The vacuum tanks include a digital closed-loop vacuum control that lets operators enter fine vacuum settings (to within 0.01 inch of water) for increased dimensional control. They also have the ability to operate at water levels under 0.10 inch to control water drool.

The NPC Micro-Medical Puller-Cutter Series addresses the challenges associated with making microbore tubing, he said.

“The tubing is getting smaller and smaller, and the wall thicknesses are getting thinner and thinner, and the durometers are getting softer and softer,” he said. “You have a very small, flexible thin-wall tubing that makes it very difficult for the puller to pull and feed and cut inline.”

One of the biggest challenges the puller-cutter series addresses is adjusting the gap between the puller belts to minimize slippage and avoid damaging the tubing during pulling. The device automates what is typically a manual process to improve efficiency.

“The typical thing was to have a hand crank to open and close the gap between the belts until you made contact with the tube in order to pull it through the tank from the die to size it,” he said. “That gap between the belts has been something left up to the operator — they could turn that crank in order to make it tighter or looser.”

But Bessemer wanted a design that would automate the process, make it repeatable and eliminate the possibility of operator error. The puller-cutters use two servo motors to precisely adjust the belt gap instead of relying on a hand crank. A processor can program into the machine’s PLC the correct belt gap for running a specific product. Once the user has determined the proper gap, it can be saved as a recipe and will always be repeatable.

“We’re not charging extra for that,” Bessemer said. “I feel that strongly, that this should be a standard feature to eliminate human error.”

That feature also can be combined with an in-line laser gauge to measure tube diameter. A processor could then specify, for example, that the puller-cutter should adjust the belt gap to accommodate the precise dimensions of the tubing. Because the equipment can measure the product diameter in real time, the puller-cutter can always maintain the proper gap. Similar features are available as options on some competitors’ equipment. However, Bessemer said the option is typically an expensive add-on, and Novatec offers it as a standard feature.

The puller-cutter series is equipped with flat belts with triangular belt wrap that precisely feed microbore tubing, according to the company. Three sets of belts include sponge, white nitrile and dual layer with sponge and silicone combination.

Precision linear slide bearings have been incorporated into the belt boom system to assure the belts are parallel in both axes to offer precise tube tracking through the belt contact area.

In addition, the Bessemer Rx-SmartMED water tanks, vacuum tanks and puller-cutters can be monitored and adjusted with a remote control in addition to a touch screen that comes standard with each device.

A 7-inch tablet that can be held in one hand serves as the remote control. The wireless tablet comes standard with the water and vacuum tanks. Operators can use the tablet to move the tank back and forth and adjust vacuum, puller speed and puller belt gap; the device also displays the water temperature.

Novatec is installing vibration sensors on the water pumps and vacuum pumps so operators can find out if there are any cavitation issues or equipment malfunctions. An eventual goal is for the software to be able to communicate to a user the number of hours between filter changes and when to change a filter.

A system for making tapered tubing is available as an option and includes additional software and a 19-inch Siemens PC-based touch screen that allows more data to be displayed. The advanced taper-tube package offers “dramatically enhanced features” that minimize the trial and error normally required during startups with processing tapered tubing, according to the company. A drop-down menu allows an operator to input information, including extruder size, material, durometer and throughput, and specify distal and proximal dimensions, transition lengths and desired line speed, as well as whether the product is single-lumen or multilumen, and symmetrical or asymmetrical.

In addition to the above data, the operator can enter the inner and outer diameters of the tubing, and the program will advise if the settings will work. If the combination won’t work, the program will recommend changes.

The new downstream medical equipment will incorporate IoT technology from Siemens and MachineSense, a subsidiary of Novatec and a Gold Partner in Siemens’ MindSphere Partner Program.

MindSphere is a cloud-based, open IoT operating system from Siemens that connects products, machine systems and plants. It helps businesses monitor the operating conditions of equipment including real-time health monitoring that significantly reduces unplanned downtime and maintenance costs. Insights from machine data also can improve workflow. The MachineSense sensors will be monitoring the water pump and vacuum blower, with an option to add power quality monitoring. The sensors will provide information relating to operating conditions, operating health, and predictive analytics relating to both. Meanwhile, MindSphere offers the services through secure connectivity and data management, according to the company.

Bruce Geiselman, senior staff reporter

Contact:

Novatec Inc. Baltimore, 410-789-4811,