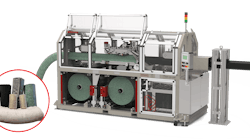

GEM Melt that flows into this new filtering system from Fimic passes through two same-sized screens placed one in front of the other. It then splits off into two equal-sized chambers; two independent valves empty contamination out of the system. The high-throughput system is designed to handle recyclers’ growing demand for bigger capacities. It can tackle all types of polyolefins, as well as PS, ABS and many other material types.

What’s new? The system, with its back-to-back filters, which debuted at the K show.

Benefits Increased throughput, with higher-quality material processing. Combining two filters in one unit, the GEM takes up less space and uses less energy than other setups, which would require two machines. Also, it has less-demanding maintenance requirements and generates less waste. Changing the screen also is easier.

Fimic srl, Carmignano di Brenta, Italy, 39-049-5957163, www.fimic.it

| Vital Statistics | |

| Throughput range | 5,500 pounds per hour to 13,000 pounds per hour (depending on material) |

| Filtering area | 861 square inches |

| Filter opening size range | 80 microns to 2,000 microns |