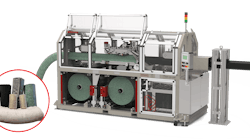

Profilemaster PMM 130 and Profilemaster PMM 160 Designed to be incorporated inline downstream of an extruder, these Zumbach quality-assurance devices use cameras that track the line of a laser across the surface of a product. They can measure as many as 200 contours per second, including diameters and angles, on a variety of parts, such as pipes and window profiles. The numbers in the model names indicate the devices’ measuring fields in millimeters.

What’s new? A turning mechanism so that system cameras and lasers can move around a product. A large opening on the side of the system allows it to be moved into a running extrusion line without the need to stop the process or cut the product that needs to be measured.

Benefits Improved contour coverage, and simplified maintenance. With their flexibility and measuring speed, the devices outperform previous systems and facilitate better production monitoring.

Zumbach Electronics Corp., Mount Kisco, N.Y., 914-241-7080, www.zumbach.com

| Vital Statistics | ||

| Profilemaster PMM 130 | Profilemaster PMM 160 | |

| Measuring field | 5.1 inches | 6.3 inches |

| Number of cameras | 4 | 6 |