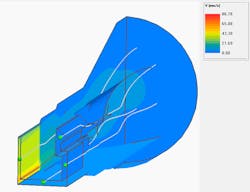

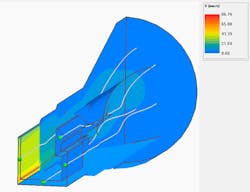

Profile Die3D Compuplast’s Profile Die3D is a module of the company’s Virtual Extrusion Laboratory (VEL) software that is purpose-built for engineering and optimizing extrusion profile dies.

What’s new? VEL Version 6.11.1, which was released at K 2019. With the new version, users take a smartphone picture of the profile and the software can digitize the image, rather than just measure it as in earlier versions. Users can then compare the digitized version with the target profile and quantify the differences. Through the simulation, they can determine how much the die geometry needs to be adjusted to correct for these differences and achieve the required part shape.

Benefits Efficient die development. By avoiding unnecessary extra iterations, users can finalize their die design more quickly, saving money and avoiding delays.

Compuplast International (USA) Inc., Williamsville, N.Y., 716-536-3426, www.compuplast.net