Processing Technologies International (PTi) and Farrel Pomini announced in April they had formed a partnership to market and sell an integrated extrusion system combining technologies from both companies.

Called the Direct-to-Sheet, or DTS, compounding line, the system combines Farrel Pomini’s CP Series II compounding extruder with PTi’s G-series roll stands. With DTS, operators can mix resins and additives, such as mineral fillers, colorants and modifiers, within the compounder, then extrude them as sheet — all with no interruption in the process.

“It lends itself to this process very well,” he said.

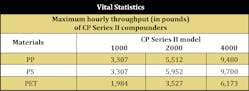

Production rates for the CP Series II compounders vary by material, Lloyd said. Of the models within the series, he expects three — the CP1000, CP2000 and CP4000 — to be the subject of most DTS customer interest. In general, the numbers in the models’ names correspond to their nominal hourly throughputs in kilograms; actual throughputs for DTS are expected to be slightly lower.

Farrel and PTi agreed to join forces on DTS to meet customer demand for a system that could extrude sheet directly from a mix of materials.

“We did have one or two compounders who were interested in expanding what they were doing,” Lloyd said. And, he said, PTi had fielded even more inquiries from among its extrusion customers. PTi and Farrel plan to sell and service the systems to their own sets of clients independently, with the first systems coming online sometime before year’s end, he said.

Besides the compounder and roll stands, the systems will include an updated version of PTi’s Titan PLC and Plus controls, said Matt Banach, senior VP of sales and marketing for PTi. They also will feature modified downstream venting.

“This is a technology offering and packaged system [that] provides the customer with a truly integrated solution backed by industry-leading compounding and sheet-extrusion expertise,” Banach said.

Both Farrel and PTi touted the efficiencies of the system. Lloyd said users, like Farrel’s customers, can benefit from opportunities to vertically integrate. Just as important, they will be able to reap considerable savings from performing two processes at once.

“DTS technology will provide processors with a unique opportunity to address sustainability concerns by producing highly mineral-filled sheet products while also gaining monetarily from the efficiencies that result,” PTi President Dana Hanson said.

Lloyd noted that, with DTS, there are fewer heating and cooling steps.

“You’re not using the energy to cool [the plastic] down, and then using energy to reheat it, so there’s a significant cost savings,” he said.

Lloyd said while the system is the only offering to result from the partnership between Farrel and PTi, the two companies are building a relationship.

“We have two established pieces that we are bringing together for the first time,” he said.

Karen Hanna, copy editor

Contact:

Farrel Corp.,

Ansonia, Conn., 203-736-5500, www.farrel-pomini.com

Processing Technologies International LLC,

Aurora, Ill., 630-585-5800, www.ptiextruders.com