With three small children and a law practice with her husband, Füllsack initially joined Motan in 2006 to handle the growing company’s legal and financial issues. But it did not take long before she was hooked on manufacturing. She eventually made the commitment to someday take over the company from her father and set about learning the products, production and marketing aspects of the business. In 2018 she became CEO. Her father, Ralf Schneider, is still the owner but is not involved in day-to-day operation of the far-flung company.

Motan was founded in southern Germany 1947 under another name. Schneider, an accountant, purchased it in 1972 and in 1973 moved Motan into the plastics industry. Today it has 550 employees and approximately 550 sales representatives selling Motan products around the world. Production is in Germany, China and India. It is a modern company that retains some of the best characteristics of a traditional organization that develops strong ties to employees and customers.

Füllsack discussed her role during an interview with Editor Ron Shinn at K 2019.

Did you ever think you would lead Motan?

Füllsack: I suppose I did absorb the culture of the company when I was growing up, but I never thought of myself as the successor. It was never my plan. Once I started, I realized that taking responsibility for just finance was not the right way to lead a business. I spent the first five years studying marketing, the products and the technical departments so I could understand the business. I tried to learn and understand everything.

Are you comfortable in the position now?

Füllsack: Yes. I have a good team. It is a comfortable situation.

What is your biggest day-to-day challenge?

Füllsack: Leading the management team. I want everyone to feel like an entrepreneur in his part of the business. I like to have an entrepreneurial spirit in every sales region to build up their markets. My challenge is to create the global thinking of Motan so we are one company. Coordinating all these individuals and bringing everything into one direction is my biggest challenge.

With operations around the world, do you get to talk to customers?

Füllsack: Yes. I am involved with key customers and every time I visit another Motan location I try to visit customers. It is very important for me to talk to customers. I also try to visit customers that are not so big. This is important for us to build for the future.

Are there recent technology achievements that make you proud?

Füllsack: We have transformed from being a materials handling equipment supplier to a materials management equipment supplier. For us, this means more than just digitization of our products. It means for the processor to be able to better understand efficiency increases in the logistics of materials.

Material management starts at material storage and goes to the processing machine and includes data at every step along the line. With our new controls, we have become good at syncing all along the line and interfacing with other equipment to provide a complete solution. Basically, it is about verification, traceability and documentation of the raw material. It has been an important step for Motan to expand into a materials management equipment supplier.

What sets Motan apart from its competitors?

Füllsack: First, our global organization. We are very close to our customers. We talk to our customers all over the world and develop creative solutions for them.

Second, we have very skilled service people. Our customers are paying for equipment that is always available to them. Out of the relationship we build by being close to them, we can help when something is not working.

Third, we are working to build very reliable products. We think about our products being dependable for our customers. We work on this quality from the design of our products to service at the end. This holistic thinking about the chain is a big advantage. This is why our customers trust Motan.

What are your customers asking for now?

Füllsack: The plastics industry in this moment is going through a bit of a crisis with the way plastics are being viewed. Processors and end users are looking for solutions to deal with reprocessed or regrind material. We are helping them optimize their systems to work with these materials. Virgin material is easy to work with because it is consistent. As soon as you start processing reprocessed material, particularly from post-consumer resin, there is no guarantee what is in it. You now have variables and we need to build equipment that can react to that.

What portion of Motan’s sales are in North America?

Füllsack: About 18 percent. The U.S. was one of our first investments for expansion in the 1980s. We are very established in the market. Later this year we plan to open a new factory and subsidiary in Mexico.

We are also planning some things in Africa. We have many multinational customers and the economies of the world are coming together now. That is an advantage for Motan. We can support our customers anywhere in the world that they go with their businesses.

Have you considered branching out from materials management equipment?

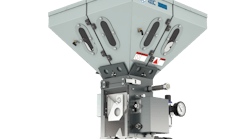

Füllsack: We work in a very narrow field: storage, drying, conveying, dosing and mixing of materials. We have considered other products, such as temperature control units or granulators, but in the end, we decided to stay with our core competencies. Our expertise is in materials management equipment.

Is workforce development a problem?

Füllsack: We are a family-owned company and we invest in our people. We have a training program that everyone must complete during their first year. There are options during an employee’s second year; some train on various job modules and some go abroad to get to know other languages and markets. There is a mentoring program where we stand a young worker next to an experienced worker to get job training, contact with customers and to learn what is important in our business.

We also have a two-year-long training program called Junior Staff Management that is very exclusive. Employees must be nominated for it. The focus is on entrepreneurship, leadership, cultural skills and business strategy. They have to work together to think about what we want Motan to be in the next five to 10 years. We put a lot of effort into this program.

I think of capital in terms of human beings. Our capital is not our money in the bank but the people who stay with the company. As long as they stay, we earn more money. The basis of our capital is our people. If people are going to the competitor and you always have to build up new knowledge, you lose money in the end.

Do you think there is a good future for the plastics machinery industry?

Füllsack: Yes. Everyone has to look at his or her role in the environment. Sustainable handling in materials management has been embedded in the Motan company philosophy for a long time. We will continue to focus on responsible handling of resources when using Motan products.

What would you like for your legacy to be when you retire?

Füllsack: I would like for our employees to think they always had a realistic chance to grow in the company and that they had a reliable person in me and in the company to make good on what they were promised. This reliability is a core value for me, for our employees, for our customers and our family.

Just the facts:

WHO IS SHE: Sandra Füllsack, CEO of Motan Holding GmbH

HEADQUARTERS: Konstanz, Germany

COMPANY FOUNDED: 1947

EMPLOYEES: 550

ANNUAL SALES: About $144 million

PREVIOUS EXPERIENCE: Practicing attorney