A human hair can be around 100 microns wide. The waste from a dust mite is even smaller — about 5 or 10 microns.

Thankfully, the human eye doesn’t register such sizes.

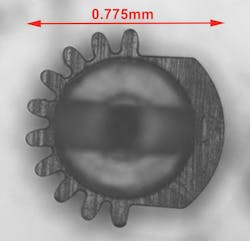

But these dimensions — the realm of “wee beasties,” first discovered by microbiologist Anton van Leeuwenhoek — are the bailiwick of micromolders. Using specialized technologies and skills, they produce parts and part features on a scale that would have bedazzled the users of early optics. Innovations in the industry make possible modern marvels, including bioabsorbable drug-delivery systems, tiny pressure monitors for eye surgery and countless components for electronic devices that seem to grow ever smaller.

Related: Isometric draws on mold making expertise; Accumold zeroes in on doing 'the impossible'

“We have molded features on a lab slide 4 microns [in] diameter by 3 microns deep, [with] microwells, 42 million of them on one slide,” said Oliver Rapp, the plant manager for NN Life Sciences in Rhode Island.

Words like “science-fiction,” “Star Trek” and “impossible” come up a lot when talking about micromolding. But pushing the frontiers of manufacturing is a way of life for molders for whom the difference between passing and failing might be no greater than the width of a split hair.

From the mold to assembly and packaging, micromolding requires a greater degree of exactitude. And it isn’t for everyone.

“We usually tell our customers, if you’ve got 50 other molders that you can quote this with and they can mold it, that’s not something we’re going to get involved with,” said Aaron Johnson, VP of marketing and consumer strategy for Accumold, an Iowa molder. “At least for us, precision is a big piece of it, and that’s the space we hover around.”

For NN and other manufacturers, including Accumold, which specializes in micro-optics, the health-care industry, among others, is driving innovation.

The process requires precision, but the word “micromolding” itself is subjective. If you make car door panels, churning out Lego blocks might be a challenge. But for plants such as NN, such parts are gargantuan. Those molders occupy a more Lilliputian world, where the part, its particular features or tolerances can be measured in millimeters and microns.

Lindsay Mann, the director of sales and marketing for MTD Micro Molding in Massachusetts, explained, though, the process doesn’t always involve molding microscopic parts.

“This has been proven to be one of the greatest myths of the micromedical device industry,” she said. “In many instances, micropart features that can be seen with the naked eye require more specialized tools and techniques than what’s required for a microscopic part with simple geometry. In micromolding, some of the most difficult parts to manufacture are larger parts with microfeatures.”

In defining micromolding, one important common denominator is tight tolerances.

“One of the challenges in making these parts is measuring the tight tolerances and being able to maintain consistent data points, specifically when used in multicavity molds,” said Stafford Frearson, VP of engineering for upstate New York molder Tessy Plastics, which makes minimally invasive surgical tools.

Some features are so small that if they were airborne, they’d enter your lungs without your eyes ever noticing.

Landing the job

Determining which jobs a shop can handle begins well before the machines start running.

“There is an artistry in what is able to be created in steel and ultimately molded in plastic, but the key to all of this is know-how,” said Tom Moyak, a sales manager for Matrix Tool, a full-service injection molder. “We look at each project on a case-by-case basis and consider resin selection, feature size, manufacturability and more to determine if we’re confident in our approach to be able to offer our customer a viable manufacturing solution.”

The Pennsylvania company takes a holistic approach to the process.

“We bring all facets together,” Moyak said. “Through advance product quality planning, we gather input from mold designers, tool makers, process and automation engineers, and quality personnel to ensure all processes work together efficiently.”

That process, Rapp said, takes “a lot of upfront, resource-hungry work.”

NN has experience making components in “astoundingly high volumes,” Rapp said. “We get involved pretty heavily early on with manufacturability and knowing that we’re designing something ... that our goal is to make millions of them a year.”

Part of that upfront work involves materials. Some of the plastics used in micromolding include PE, PP, polyamide and PC, as well as more exotic and expensive materials, such as polyoxymethylene, polysulfone, polybutylene terephthalate, acrylic, PEEK, polyetherimide, liquid crystal polymers and bioabsorbables.

“Depending on how demanding the details of a given part geometry are, microparts can begin to push the limits of how an engineer might expect a typical non-Newtonian fluid to behave,” said Patrick Haney, an R&D engineer at MTD. “Once you have surpassed the threshold of extreme shear and cooling rates, the resulting product (unless expertly manipulated) will rarely demonstrate the properties that are forecasted for the given material and mechanical functions. Due to these phenomena, successful micromolders must find creative and alternative ways to optimize their processing parameters to ensure that the resulting process is grounded in as much scientific data as possible.”

Handling IT in-house

For some micromolders, including Matrix, MTD, Isometric and Accumold, a key to taking on the challenge is bringing as much work in-house as possible — including mold making.

Matrix, for instance, employs 15 engineers, as well as a “double-digit” number of journeyman toolmakers, Moyak said.

“This unique mix of skills allows Matrix Tool to offer our customers cutting-edge engineering services,” Moyak said.

“The first and foremost challenge is generating a good, solid mold design capable of longevity even though the core pins and ejector pins are hair sizes,” Bibber said. “The mold design should lend itself to manufacturability and suit the microfabrication methods such as micro EDM [electrical discharge machining], microwire EDM, five-axis micromilling, grinding and so on.”

Gate freeze and gate location are big issues.

MTD has successfully molded an ophthalmic part that weighed 0.00000313 gram. The gate measured 0.0018 inch by 0.0008 inch.

“Keeping the gate open long enough to fully pack the part is sometimes an issue,” MTD operations manager John Clark said. “We see gate freeze in less than 300 milliseconds, which isn’t a lot of time to fill the part and pack.”

In addition, part geometry can cause issues in filling, especially when MTD’s designers can’t put the gate in the optimal location.

“Since the parts we deal with are so small, the best gate location at times is on a critical surface that we have to avoid,” Clark said.

Accumold takes the all-under-one-roof approach further — it runs the molds it makes on its own presses.

Established 35 years ago by a pair of mold makers who recognized the coming demands of the electronics industry, Accumold believes being a machine builder is “part of our DNA,” Johnson said.

“It gives us the control and the kind of efficiencies that we believe are important to serving our industry,” he said.

Building its own presses and molds ensures Accumold’s processes minimize material usage and have the speed and efficiencies scaled for microparts.

In addition to 80 proprietary Micro Mold machines, the company has 70 small presses from Sumitomo, which are used for slightly larger parts.

“We have up-to-35-ton Sumitomo machines for what we call our small molds — that’s for the larger components, maybe with microfeatures or other critical details,” Johnson said.

The company calls its 35-ton injection molding machines “monster presses,” he said.

Forming a partnership

Machine builders tout their services to micromolders. For instance, Nissei has supplied machines to NN.

“As in all molding, the molds are getting more complex and, as a manufacturer, we have to adapt, and the best way is to listen to the customers,” said Joe Kendzulak, a senior technical adviser for Nissei. “We are working on a micromolding project now that is having us use two different … technologies merged together to fulfill the customer’s needs. So, the relationship is very important.”

Finding the right machine can be tricky, said John Reynolds, engineering manager at NN’s Rhode Island plant. Many machines aren’t designed for small-enough shot sizes, so material is wasted on runners, rather than parts. But, he said, “I have seen some movement. Barrels are getting smaller and smaller.”

Makuta is an Indiana molder that produces millions of micro- to small-sized parts each month for customers in the medical, pharmaceutical, microfluidics, electronics, office automation and automotive industries. Like Accumold, it uses Sumitomo presses.

“In terms of controlling precision, the requirements for both the mold and the processing parameters are magnified tremendously compared with traditional injection molding,” company President Stu Kaplan said. “A minuscule change in material viscosity, for example, that might be irrelevant when molding a standard part could have serious implications in a micromolded part.”

Extracting good parts

While refinements to molds and presses might be the most obvious requirements of micromolding, equipment demands include a host of other technologies. Molders, including Makuta, NN, Isometric, MTD and Matrix, reported using a variety of specialized technologies to handle the challenge.

“In order to develop and monitor a scientific process, molders need the proper tools,” Kaplan said. “This requires scales, pyrometers, calipers, microscopes and others. We also need our molding machines to monitor a wide range of parameters within extremely tight tolerances to ensure shot-to-shot consistency. If any of those parameters are not met, the parts are automatically rejected.”

What works for small volumes often isn’t enough for large commercial runs. The scaling-up conversations echo throughout the process at NN, where what starts as a prototyping project can evolve into a huge, ongoing program.

At Isometric, which uses 12 micromolding machines, including Sodick presses with clamping forces ranging from 10 to 60 tons, in-house automated assembly systems remove parts — sometimes dust-speck-sized — from molds. Custom-

designed vision inspection systems then determine whether they are in spec.

MTD, too, requires solutions that aren’t off-the-shelf. It produces custom EOAT for each part it manufactures.

“We need to build our own custom EOATs to help demold the part,” said Jared Cicio, MTD’s molding and production manager. “Most of the time, this is achieved by creating a ‘nest’ that the part can fit into, sometimes with a vacuum assist. We also use these EOATs to position parts in front of our checker and in-line inspection cameras.”

MTD also often uses specialized trimmers with microcutting tips to trim parts, he said.

The company uses a fluidized sand bath to clean internal areas of the flow path in injection molding tooling instead of using drills or wire brushes, which could leave contaminants.

It also has developed its own fixtures for holding parts while they are measured.

“Measuring tiny parts consistently often requires tiny fixtures that do not obscure the dimensions,” quality-control technician Maggie Beauregard said. “MTD has several innovative fixtures, including our rotary [fixture] and even mirrors, to help measure parts.”

Rapp said NN spends a considerable amount of time scouting the latest metrology technologies.

Matrix also employs an arsenal.

“As parts get smaller, the total tolerance follows suit, and this leads to metrology challenges,” Moyak said. “Quality challenges typically revolve around appropriate tooling-related equipment needed to machine the ultra-high-precision components as well as specialized inspection equipment that allows for the verification of steel dimensions and final molded part dimensions. Specialized inspection equipment can include magnification aids such as high-magnification optical comparators and microscopes, high-resolution optical gauging/video measuring equipment, high-resolution camera systems and automated in-line vision inspection systems.”

Measuring up

Being on spec, though, requires a bit of art, as well as science. Johnson compared Accumold’s micromolding approach to a musician playing a Steinway piano.

When it comes to small parts and the engineering resins used to make them, companies need employees who break the mold— figuratively, at least, in terms of their skills.

For instance, Accumold’s technicians have training in traditional tool and die building, but they also need additional instruction at Accumold on how to adapt those skills to micromolding.

To ensure an adequate supply of skilled workers, Accumold awards scholarships to students to attend a community college’s tool and die program.

“They will need the basic machine skills, but then we come in and teach them and train them on the Accumold way and the way we do things,” Johnson said. “That’s really kind of the pattern throughout the rest of our organization. Whether it’s our press operators or our quality technicians or quality engineers, it’s all about, here is the basic skill set we need, but then here’s the Accumold way. … We do a lot of internal training and ongoing training as an organization.”

To handle the complexity of building molds with microfeatures and to meet the company’s goal to bring products to market quickly, Accumold’s mold makers specialize. Specialty areas include mold design, core pin construction and cavity construction. The company employs 75 workers in its toolroom, and 15 to 20 of those workers might be involved with a specific mold.

“It’s not one guy making a mold,” Johnson said. “It’s a team of people and the different specialty machining processes that they’re involved with, and it all has to come together. It’s like doing a jigsaw puzzle and you have 15 pieces made by 15 different people, but at the end of the day, they all have to fit and make the right picture.”

It’s not for everyone.

“The operators we’re talking about, not everyone can do it,” said Reynolds, the engineering manager at NN, where different operators work with either micro- or non-micro-sized parts.

“It comes down to eyesight, it comes down to attention to detail, it comes down to being comfortable working at a microscope. ... It can be a grind,” he said.

Bruce Geiselman, senior staff reporter

Karen Hanna, associate editor

Contact:

Accumold, Ankeny, Iowa, 515-964-5741, www.accu-mold.com

Isometric Micro Molding Inc., New Richmond, Wis., 715-246-7005, [email protected], https://isomicro.com

Makuta Inc., Shelbyville, Ind., 317-642-0001, https://makuta.com

Matrix Tool Inc., Fairview, Pa., 814-474-5531, www.matrixtoolinc.com

MTD Micro Molding, Charlton, Mass., 800-998-5549, https://mtdmicromolding.com

NN Inc., East Providence, R.I., 401-434-3040, www.nninc.com

Tessy Plastics Corp., Skaneateles, N.Y., 315-685-1539, https://tessy.com