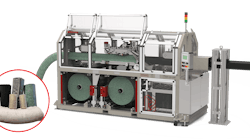

B4 IML system At K 2019, Beck Automation displayed its B4 in-mold labeling system in a manufacturing cell producing 200-milliliter thin-walled containers. A KraussMaffei high-performance Elion 1750 injection molding machine ran a four-cavity mold created by Glaroform AG. The B4’s in-mold labeling functions were monitored by Intravis’ IMLWatcher vision inspection system.

What’s new? Closed-loop label adjustment. The IMLWatcher checks the position of the labels each cycle, and the B4’s label magazine automatically adjusts to correct for any misplaced labels.

Benefits Reduced scrap. Also, the B4’s lightweight main arm and linear motors allow for dynamic movements and short cycle times.

Beck Automation AG, Oberengstringen, Switzerland, 41-44-751-84-44, www.beck-automation.com