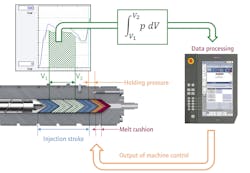

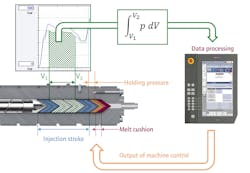

HiQ-FlowDesigned for use with Wittmann Battenfeld presses’ Unilog B8 controls, this optional software module monitors the injection pressure curve and compensates for viscosity irregularities. It takes as many as 400 measurements along the injection stroke and automatically corrects for deviations outside the margins specified by the operator. By either adjusting the holding pressure or shifting the changeover point to holding pressure, the module can compensate for fluctuations in temperature and material viscosity.

What’s new? Faster program start-up, just by turning on the software. In a demonstration at K 2019, an EcoPower 55, a 61-ton, all-electric injection molding machine, manufactured PC clothespins in a four-cavity mold, while the machine’s HiQ-Flow module automatically compensated for material viscosity fluctuations.

Benefits The ability to maintain a stable process, allowing for the manufacture of high-quality parts. Upgrades to HiQ-Flow have made it easier to use.

Wittmann Battenfeld Inc., Torrington, Conn., 860-496-9603, www.wittmann-group.com