Suppliers are offering new and upgraded drop-in hot-runner systems, which can dramatically simplify the incorporation of hot runners into injection molds. The new drop-in systems are designed to save time and money for mold makers and processors.

MOLD-MASTERS

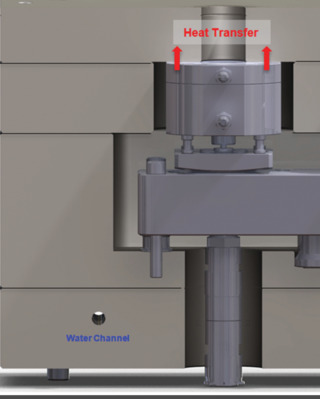

Last year, the company added two nozzles for the system: the F3000, which handles shot sizes of less than 15 grams, and the F8000, for shot sizes of up to 5,000 grams. Most recently, the focus is on adding waterless pneumatic actuators, a first for the company’s hot-runner systems. The actuators transfer heat to a mold’s existing water-cooling channels.

Mold-Masters calls this process Passive Actuator Cooling Technology (PACT). A key benefit, the company said, is “eliminating the hose-plumbed cooling circuits of traditional actuators,” which “simplifies mold design and its operating requirements.”

The company said PACT allows for simultaneous shutdown of the mold-cooling system and the hot runner. And with fewer connections to manage, mold changes can be completed more rapidly than with conventional cooling systems, a plus for molders with short production runs.

Mold-Masters plans more enhancements to components for its Fusion Series G2 system this year to improve capabilities and minimize downtime. They include:

• The F2000, an addition to its nozzle lineup. The company did not release details about the nozzle, which will be targeted at technical parts for automotive under-the-hood applications.

• The ability to adjust the height of the valve pin for all Fusion Series G2 actuators. This option will make it easier to adjust protruding pins without removing the clamping plate. Also, the company will offer a valve pin with a quick-release decoupling feature that allows the pin or actuator to be removed independently. It also will feature an anti-rotation mechanism.

• Nozzle sleeves that will protect heaters from damage during assembly or disassembly, an aid in avoiding downtime.

HASCO AMERICA

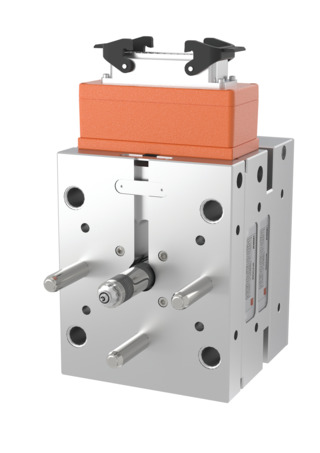

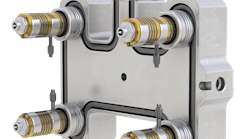

Hasco’s new H44201 and H44202 hot halves with single-needle valves come inThe hot halves, introduced late last year, are designed to both reduce the time it takes to design and build molds and to decrease manufacturing costs. The components are configured to meet individual specifications, with relevant CAD data available in days, the company said.

Each ready-to-connect system easily attaches to a fixed mold plate and is guaranteed by the company to be leak-free. Hasco supplies the hot halves with USB 2.0 data memory that stores part lists, drawings and measurements, as well as user-loaded information about mold and injection parameters.

The hot halves incorporate Hasco’s Vario Shot nozzles, the tips of which are designed for high thermal conductivity, wear resistance and low shear.

Pat Toensmeier, contributor

Contact:

Hasco America Inc., Fletcher, N.C., 828-650-2600, www.hasco.com

Mold-Masters Ltd.,

Georgetown, Ontario, 905-877-0185, www.moldmasters.com