By Karen Hanna

Molders and mold makers want a little bit of everything from their hot runners. Hasco’s customers, for example, are demanding technologies that can handle reinforced, highly filled plastics, as well as technical resins, such as PC, polyamide and high-performance polyamide. The company, which makes mold components, reported customers also want short cycle times, homogenous temperatures and durable technologies.

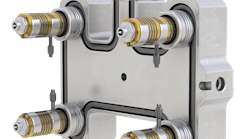

Hasco’s latest innovations include the H107940, a modular needle-valve unit for use with hot-runner systems with valve gates. Built with a compact housing that contains a piston and connections, the H107940 is designed primarily for fully wired and piped systems.

The H107940 is pre-assembled and has a flanged design that allows it to be mounted directly on a hot runner.

A pneumatic device, it’s especially appropriate for clean rooms, and it can handle a wide range of applications and materials.

According to Hasco, the H107940 offers a number of benefits. It is easy to install, and, because of its compact, all-in-one design, mold makers don’t have to machine the precise mounting space for the piston. There also is no need for supply drill holes, which are a potential source of damage to the O-rings, as well as dirt that could contaminate the system.

The needle in the H107940 can be adjusted without dismantling the unit by twisting the valve-pin holder from the rear.

Karen Hanna, senior staff reporter

Hasco America Inc., Fletcher, N.C., 828-650-2600, www.hasco.com