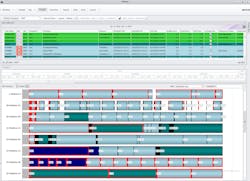

What’s new? The launch of InFocus Operation Resource Planning (ORP), the third product in the InFocus portfolio, as well as modifications that make InFocus Machining applicable to general manufacturers not involved in mold making. Taking into account factors such as machines’ weight capacities and workpiece-size limitations, InFocus ORP automatically schedules jobs to optimize mold shops’ resources. In addition, R.E.R. Software has updated InFocus Machining so that the program can now evaluate key metrics, such as overall equipment effectiveness, total effective equipment performance and overall operations effectiveness, for a host of manufacturers.

Benefits Optimization of job resources. Overall, the InFocus suite helps mold makers address one of their greatest challenges — the lack of skilled labor — by allowing them to optimize their resources, getting the most out of both their machinery and their employees’ expertise. With the software, users can reduce idle time and better estimate job costs.

R.E.R. Software Inc., Rochester, Mich., 586-744-0881, www.rersoftware.com