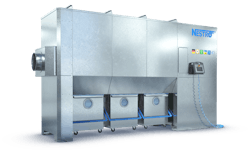

NE J deduster Nestro manufactures air filtration, air purifier and deduster units for a wide range of industries, including plastics and plastics recycling facilities. Its NE line of dedusters is designed for small to mid-sized businesses, and the high-efficiency dedusters are configured with the fan located after the vacuum filter unit, so the fan doesn’t come into contact with the material being filtered.

What’s new? The NE J line of mobile dedusters, which have an updated, modular design that employs high-efficiency IE5 motors. The frequency-controlled motors are kept running at the optimal operating point, and are quieter than their predecessors. An automatic fire-extinguishing system that hermetically seals the unit to suffocate fire is also new. The NE J line is scheduled to be available in the first quarter of 2022.

Benefits Low operating costs. Energy costs can be 22 percent lower than for earlier units operating with IE3 motors. The NE J line is available in four models, with air flows up to 335,489 cubic feet per hour. Disposal options include dust bins, separator locks and a briquette press. Each unit has a wired touch-panel terminal that gives the operator more freedom of movement around the deduster. The NE J units can be delivered in segments to pass through narrow spaces and can then be assembled on site.

Nestro Lufttechnik GmbH, Schkölen, Germany, 49-36694-41-0, www.nestro.com