By Bruce Geiselman

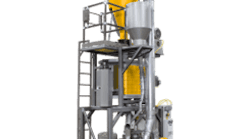

Maillefer displayed the new MXD series of high-performance extruders in 45mm and 80mm sizes during the K Show in Dusseldorf, Germany.

“Indeed, the MXD is a new series of machine released this year,” André Gosselin, marketing manager for Maillefer, told Plastics Machinery & Manufacturing in an email. “They are modern machines aimed at pipe and tube applications.”

The 45mm and 80mm sizes are the first to be rolled out. The company is in the process of developing 30mm, 60mm and 100mm models. The 30mm and 45mm models will be available in either a standard flow-rate version or a higher-output version. The extruders are offered with L:D ratios of 24:1, 30:1 and 36:1.

The higher-output version includes a more powerful motor and gearbox, Gosselin said. In addition, specially designed screws and barrels, suitable for processing PE for pipe and tube applications, are available.

The new extruders have a compact footprint, according to the company. The design shortens melt distances to the extrusion head, optimizes throughput and provides overall extrusion efficiency, while allowing the machines to overcome cumbersome layouts.

The MXD line is being offered in conjunction with the earlier MXC generation. The new generation is designed to best meet the performance needs of pipe and tube producers with up-to-date motors, drives and controls. The drive and motor sizes can be fitted to the producer’s application and processing requirements.

MXD extruders are Industry 4.0-ready. They have the connections required to integrate with existing extrusion lines and with smart monitoring software including D-S Activ-Check, which is offered by Maillefer’s parent company, Davis-Standard.

The 30mm and 45mm models can be used as either main extruders or auxiliary machines that might perform applications such as applying stripes, skins and adhesives, according to the company. Various hardening and surface treatments are available for corrosive and abrasive compounds.

Bruce Geiselman, senior staff reporter

Maillefer North America, Surgoinsville, Tenn., 423-817-2440, www.maillefer.net/en/