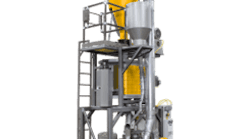

Dreno Covering Italy’s Baruffaldi offers processors its Dreno Covering machine for both inline and offline use to automate covering perforated or slotted corrugated pipes with PP Geotextile, also known as TNT. The Dreno Covering machine can process both rigid single-walled and flexible double-walled pipes with diameters ranging from about 2 inches to about 8 inches. It wraps and welds the TNT in a continuous process using an ultrasonic welding head. Baruffaldi produces downstream equipment for pipe production under its Primac brand.

What’s new? A series of updates to the Dreno Covering TNT/50-200 machine, including a smaller footprint.

Benefits Increased production speed — which can now reach more than 98 feet per minute. Safety guards have been improved to better protect operators. The Dreno Covering can hold two coils of fabric, and its automatic changeover eliminates the need to interrupt production for coil changes. It also can accommodate any type of geotextile to meet customer requests and specific applications.

Baruffaldi Plastic Technology Srl, Fusignano, Italy, 39-0545-52652, www.baruffaldi.eu