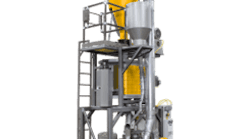

1,850mm die As exhibited at the K Show, Comelt’s custom-built sheet die features a coat hanger manifold, flex lip, flex restrictor bar, sliding lower lip, lip heating and adjustable, external deckling with a slot.

What’s new? The 1,850mm die, with a variety of features developed this year and last.

Benefits Customizability. All of Comelt’s products are tailor-made, based on factors such as width and sheet thickness. As part of its K Show demonstration, the company set out to show potential customers its ability to provide dies, ranging in width from 150mm to 3,000mm, that can provide high-quality single- and multi-layer sheets for applications such as automotive interiors, high-quality furniture and suitcases. Featuring a special adjustable external deckling system with hydraulic drive system, as well as a special manifold design for handling sensitive materials, the 1,850mm die was designed to handle sensitive materials and ensure maximal machine uptime, precision and product quality. Comelt’s range of products includes multi-layer, co-extrusion and multi-manifold slot dies, as well as feedblocks, sheet and blown film dies and spinnerets. Additionally, Comelt places a special emphasis on creating technologies for handling recycled materials.

Comelt Collin Melt Solutions, Tucker, Ga., 678-325-6708, www.comelt.at/en