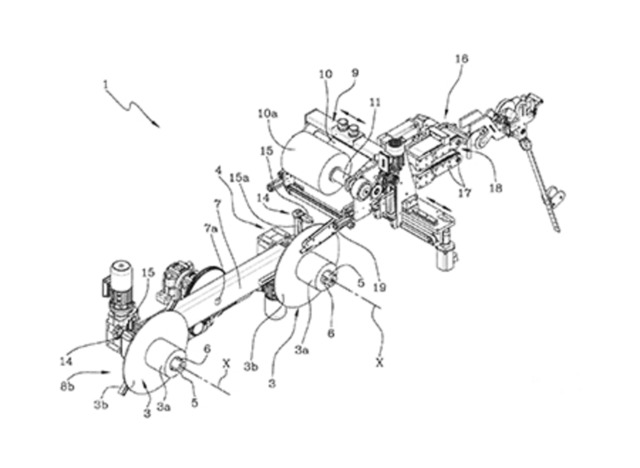

An invention from FB Balzanelli Srl, Milan, aims to automate the process for affixing a tube or flexible profile to a winding spool and to improve the quality of the finished coil.

A typical method of attaching the leading end of the extruded product to the spool involves a locking device or clamp outside the "shoulder" at the edge of the spool. This method does not produce an optimally aligned coil and leaves the leading end of the product projecting outward from the finished coil, according to the patent. Another solution avoids these problems by using a pneumatic locking device to hold the end of the tube to the spool's core, but this requires a specially modified spool.

The invention includes a drive mechanism for rotating the spool and a delivery system for winding an "elongated retaining element" around the core. A type of film acts as a retaining element to hold the end of the extruded product in place. The invention is adaptable to any type of spool.

Patent 10,046,943; issued Aug. 14

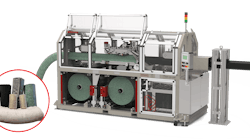

Extrusion. Windmöller & Hölscher KG, Lengerich, Germany, has applied for a patent for a film extruder that makes material changes easier on the machine operator.

Before processing a new resin, the old resin must be discharged from the extruder's feed unit. Typically, a machine operator must hold a container to catch the resin during the entire process. This can be physically demanding for the worker as well as time-consuming when multiple extruders for multilayer film lines are involved.

The invention is an extruder with at least two feed units; each feed unit has at least one discharge opening with a closure and a container interface. The operator fastens a discharge container to the interface and opens the closure. Alternatively, the discharge opening can open automatically. The interface holds the container in place, freeing the operator to repeat the procedure with the other extruders.

Patent application 20180162034; published June 14

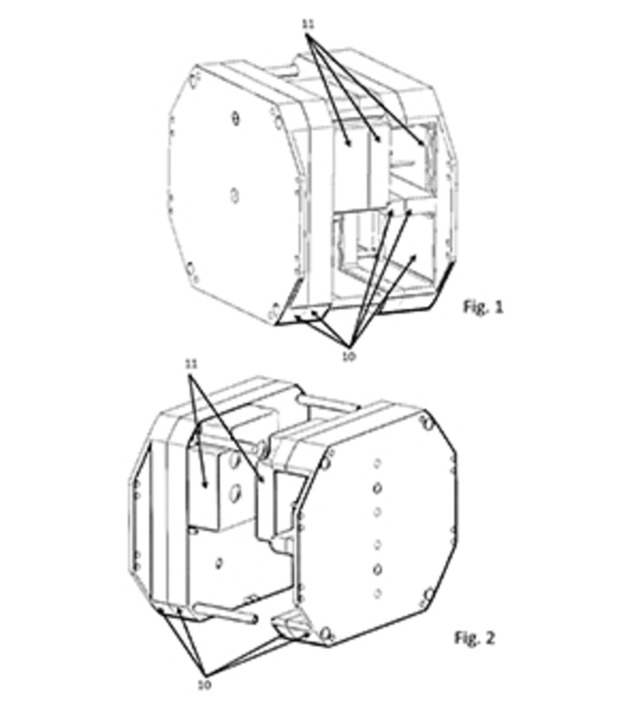

Mold base. Sika Technology AG, Baar, Switzerland, has applied for a patent for a mold base for injection molding automotive body and structural components. The invention facilitates rapid changes of mold insert assemblies and may reduce tooling costs due to its modular design, according to the patent application.

The base has multiple bridge manifolds with openings for feeding material into sub-manifolds.

"An important feature of the invention is the first and second control valves which allow control [of] for example flow and/or pressure from one sub-manifold to another sub-manifold," the application states. Existing technologies provide control only from gate to gate.

The technology can lower tooling costs by reducing the number of components mold makers need to build. It also can improve part quality by reducing flash and short-shot defects, according to the application.

Patent application 20180178426; published June 28

Degassing. Brückner Maschinenbau GmbH & Co. KG, Siegsdorf, Germany, has received a patent for a device that degasses polymer melts used to make film. The device includes a vacuum separator with a tank, cooling pipes, a collection chamber and a cleaning device with a scraper.

The vacuum units of traditional melt degassing system can be damaged by an accumulation of gases and liquids, increasing the need for cleaning and maintenance.

The invention's vacuum separator offers improved, double-walled cooling tubes that easily can be cleaned with the scraper. This increases the life of the vacuum system, according to the patent.

Patent 9,975,278; issued May 22

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received a patent?Contact [email protected]