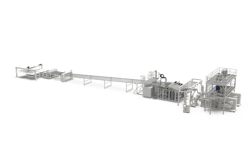

High-speed extrusion lines Battenfeld-Cincinnati’s high-speed extrusion lines for sheet production feature three compact extruders and the company’s Multitouch XXL roll stack. The lines have screw speeds of up to 1,500 revolutions per minute and throughputs up to 6,614 pounds per hour. Optimized melt residence times provide homogenization without thermally or mechanically damaging the resin.

What’s new? The ability to make high-impact PS boards for refrigerators and other white goods. Two size 75 extruders plasticize the core layer of the boards, which are up to 6mm thick and up to 3.9 feet wide, and a coextruder applies the glossy surface layer. The roll stack, which has 7.9-foot wide rolls, creates the ideal cooling conditions for making boards with tight thickness tolerances. The roll stack combines two rolls for pre-calibration of the sheet, followed by several more rolls.

Benefits High-quality sheet and cost savings. The extrusion lines can produce sheet that is half as thick as that produced by typical lines equipped with conventional three-roll roll stacks. This saves money and has ecological advantages due to reduced raw material consumption.

Battenfeld-Cincinnati USA, McPherson, Kan., 620-241-6843, www.battenfeld-cincinnati.com