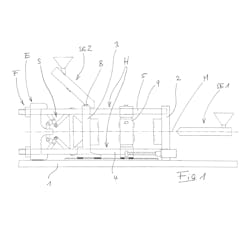

The invention has a machine bed and a fixed mold-clamping plate with an injection unit. At the opposite end of the machine axis from the first mold-clamping plate is an end plate, which is braced against the machine bed.

The end plate is associated with a closing assembly. The closing assembly acts on a movable mold-clamping plate that also has an injection unit. Between the second mold-clamping plate and the first mold-clamping plate is a turning unit that uses a rotary drive to turn around an axis perpendicular to the machine axis. Both the movable mold-clamping plate and the turning unit move along a set of linear guides. The turning unit is shifted along the machine axis by at least one longitudinal positioning drive, or in some instances an upper and a lower drive, which may be synchronized mechanically, hydraulically or electrically.

The linear guides transfer the weight of the support structure and mold-half carrier directly into the machine bed.

Extending from the fixed mold-clamping plate to the end plate are two upper and two lower bars. The rotational acceleration of the mold-half carrier is transferred to these bars via at least one bracing guide.

According to Ferromatik’s patent, these design elements substantially reduce the reaction torque exerted on the support structure, and, compared to IMMs that are not coupled to such bars, the overall axial length of the support structure can be greatly shortened. With the reduced reaction torque, the linear guides can be placed closer to the machine center, so that they transfer weight with minimum bending load. The decreased bending load permits a relatively lightweight design of the support structure.

The arrangement of the linear guides also takes advantage of the fact that IMMs with a turning unit don’t need the space between the bars for ejection of parts, because ejection can take place to the side when the mold-half carrier rotates 90 degrees. This also allows a common modular design for IMMs with or without a turning unit, which provides cost advantages.

Patent 10,046,495; issued Aug. 14