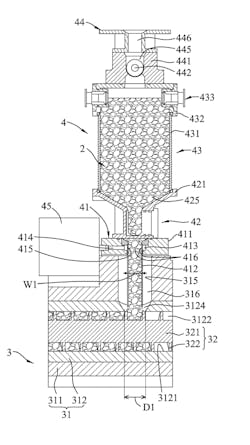

Through “the configuration of the supply tube which is spaced apart from the extruder screw … the plastic [granule] is provided with a large activity space so that the plastic granules can be prevented from being squeezed and crushed into fragments,” the application states.

This eliminates the problem of resin fragments adhering to the flights of the extrusion screw, turning black due to excessive heating and ultimately causing part defects.

Patent application 20190111587; published April 18

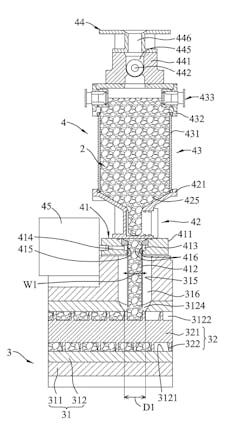

Parison storage. A newly patented storage system comprising a conveyor, chutes, drawers, control unit and database provides a place for parisons to accumulate in the event of a shutdown of a blow molding machine. The system also involves a washing bay with nozzles and ultraviolet light sources, so users can sanitize the drawers and maintain an aseptic environment.

“The loading and unloading bays are equipped with respective manipulators (automatic handling means) for picking up and moving the objects stored in the storage system,” states the patent awarded to Sacmi Cooperativa Meccanica Imola Societa Cooperativa, Imola, Italy.

Ideally, the storage system employs an optical system to count and keep track of items in storage.

Patent 10,196,211; issued Feb. 5

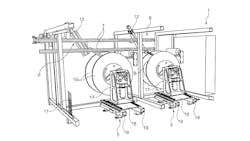

Tube winder. A device for winding microduct extruded tube onto a core overcomes problems with tube kinks, slow speeds and the need for manual intervention, according to a patent awarded to KraussMaffei Technologies GmbH, Munich, and Graewe GmbH, Neuenburg, Germany.

The invention is designed to handle tubes with outside diameters ranging from about 2mm to 20mm. According to the patent, winders for such tubes typically feature a displaceable laying arm that moves transversely to the feed direction of the microduct tubes.

“Unfortunately, a large amount of play occurs here and results in inaccuracies which entail a poor laying pattern. In extreme cases, even a winding interruption can occur,” the patent states. “In order to prevent these problems, manual laying is frequently resorted to.” Tensile stress during winding also can cause the tube to be elongated, adversely affecting the precision of the tube’s dimensions.

Patent 10,266,363; issued April 23

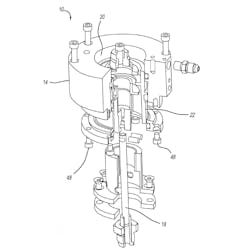

Sequential valve gate actuator. Magna Exteriors Inc., Concord, Calif., has received a patent for a hydraulic sequential valve-gate (SVG) actuator for an injection mold.

According to the patent, after 30,000 to 50,000 shots, conventional actuators are prone to leakage and sluggishness due to internal seal failures.

“Sluggishness in pin movements creates part defects that are difficult to determine the root cause of,” the patent states. “However, it is believed in many cases that these defects and part failures are due to poor reaction time of the actuators, which make the SVG pin move erratically.”

The combination of seals allows the actuator to last more than three times longer than traditional actuation valves, according to the patent.

Patent 10,267,429; issued April 23

Baler. The U.S. Patent and Trademark office awarded a patent to Catawba Baler & Equipment LLC, Burlington, N.C., for a baler featuring improved access to the compression chamber to make it easier to deal with material blockages.

The baler, which can be used for compressing recyclable plastics, metal or paper for transport or recycling, features an access door that can easily be moved between two positions, according to the patent. When closed, the door forms part of the wall of the compression chamber; when open, it allows for the passage of jammed material, which can be pushed out via the baler’s compression ram. In one embodiment, the access door features a pair of opposing hydraulic actuators that support, raise and lower the door.

The invention eliminates problems associated with traditional baler designs, in which material clogs around the rams, shear bars or other internal components, requiring significant manual labor to open and clean the chamber, the patent states.

Patent 10,245,799; issued April 2

Sorting technology. SRI International, Menlo Park, Calif., has patented a process for sorting mixed materials using electroadhesive grippers. The invention can help automate recycling operations in which items need to be sorted based on their material composition.

Conventional robotic grippers typically use either suction or mechanical actuation to grip objects. Suction grippers generally require smooth, clean, dry and flat surfaces, which limits the types and conditions of objects that can be gripped, according to the patent. Grippers employing mechanical actuation may have a limited ability to grasp fragile objects. Additionally, mechanical actuation can require devices, such as mechanical pumps, that are less than ideal for use in robotic arms, due to their weight.

The lightweight electroadhesive grippers described in the patent overcome those limitations. For example, “such an electroadhesive gripping system can be adapted to hold, move or even pick and place a wide variety of objects, including small, dirty and/or fragile objects,” the patent states. Additionally, it can select objects based on material composition, surface area, weight, thickness, shape or recognizable images or bar codes.

In one embodiment described in the patent, a pair of curtain grippers polarized with 4 kilovolts would be able to adhere to the sidewalls of a plastic bottle or a non-cylindrical plastic article because such grippers can conform to a variety of shapes.

Patent 10,232,383; issued March 19

Compactor. A German inventor has patented a key component of a compacting device that is used to flatten PET bottles to prepare them for transport or recycling. Hermann Schwelling, managing director of Hermann Schwelling Maschinenbau, Salem, Germany, invented a pressure roller that uses less energy when operating and reduces maintenance requirements, compared to existing technologies.

Additionally, “the compressed bodies [containers] have greater shape stability, so that during the subsequent recycling process, fewer disruptions in conveying of the compressed bodies occur; in the recycling machines themselves and also toward the recycling machines,” the patent states.

The rotating device has multiple, specially designed projections on its surface and is set at a distance from a counter bearing, forming a gap through which the containers pass.

The device also is appropriate for use with other types of plastic bottles, as well as metal cans.

Patent 10,195,805; issued Feb. 5

Patents and patent applications can be viewed at www.uspto.gov

Have you applied for or received a patent? Contact editorial@plastics machinerymagazine.com