Anyone who’s ever tried to glue together the pieces of a child’s broken toy knows the struggle: Plastic isn’t inclined to gluing or painting.

Special treatments — including plasma, flame, corona and chemicals, such as primers and solvents — increase the surface energy of parts, making it possible for substances like paint or glue to “wet out” — to flow evenly over a surface and bond to it. By contrast, low surface energy — the condition of most untreated plastic parts — produces the opposite effect, causing, for example, water to bead up, rather than spread out, on a newly waxed car.

A number of companies have recently introduced technologies that improve surface cleanliness, and either increase or measure surface energy, or wettability.

BTG LABS

BTG Labs, which makes instruments that test surface energy, recently put one of its latest innovations, the Surface Analyst XA, to work for a customer that makesTo achieve lubriciousness, the manufacturer treats the tubing surfaces with plasma, then coats them with polytetrafluoroethylene. The manufacturer had no in-line method to verify the effects of the plasma.

The closest solution was dyne inks, which were limited to laboratory use. Dyne inks are special substances that, when applied to a surface, flow outward or bead up. They are a conventional method of measuring surface energy, but they are inconsistent, and, without an in-line surface cleanliness gauge, BTG Labs marketing coordinator Pierce Geary said the tubing manufacturer could not guarantee its product and risked failures in the field.

The Surface Analyst XA gave the tubing manufacturer a new option. BTG demonstrated the Surface Analyst XA to the company, showing that the instrument can achieve objective, quantifiable results without damaging parts. The device can make more than 5,000 surface-energy readings per hour based on how a drop of highly purified water behaves when it touches the surface of a part.

The Surface Analyst XA integrates seamlessly into a manufacturer’s production line and saves measurement data for later use, Geary said. It gauges surface conditions in 2 seconds based on the pattern, or contact angle, the water droplet makes as it expands. A clean surface has high-energy molecules. The purified droplet also has high-energy molecules that are attracted to those in a clean surface and that spread out at a quantifiable rate determined by water volume and contact angle. A contaminated surface, in contrast, is low in molecular energy and will cause a droplet to bead up, as the droplet’s high-energy molecules will mostly be attracted to themselves.

Using the Surface Analyst XA, the tubing company measures every tube to verify that it has been properly plasma-treated. It can guarantee that each part is ready to hold coating evenly, preventing failures. Furthermore, as the device records and saves every measurement, the manufacturer collects data for audits and R&D, which are useful in gaining FDA acceptance for the product and process.

ENERCON INDUSTRIES

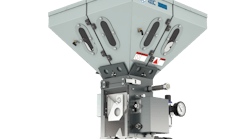

Enercon Industries specializes in plasma-, corona- and flame-treatment technologies. Its latest developments include the Flame Series Pro flame-treatment system and the Blown-ion 750 plasma-treater.

“The system monitors itself, whether it’s mounted on a robot or a conveyor line. No operator input is necessary,” Lee said. “This solution can be much more economical as compared to other gas-monitoring systems like oxygen analyzers or mass flow, with the same consistency of treatment.” Features include an intuitive touch screen that guides users through operation, fault logs and other functions.

Enercon Industries also has expanded its portfolio of plasma-treating instruments with its introduction of the Blown-ion 750, which incorporates the company’s MultiPort technology — application heads released about a year ago that enable the device to treat sections as wide as 3 inches in a single pass. In contrast, Lee said most plasma systems treat 0.5-inch widths. “We treat up to 3-inch widths with the same power per area as standard half-inch treaters,” Lee explained. “This allows us to treat wider areas with full power at extremely high speeds while emitting uniform treatment. Also, the [treatment] price per linear inch is more economical than an array of smaller heads treating the same width.”

Lee said that customers are beginning to use Enercon Industries’ Blown-ion systems, as well as flame treatments, to increase the surface energy of composite parts, thereby improving bond strength and making the process repeatable.

Composite parts are popular because of their strength-to-weight ratio, but they have relatively low surface energy. The solution has generally been hand sanding and cleaning to increase surface energy and remove excess resin. But, as with any hand preparation, there is variability. With plasma treaters, users see greater consistency, along with a significant reduction in labor per part — up to 75 percent in some applications, he said.

3DT

3DT produces corona- and plasma-treatment systems for diverse products, among them solid parts with complex shapes. Its new products include the PolyDyne Pro Foam treating system; it also recently released the UltraDyne generator for corona treatment of printable cups and tubes.

Designed to treat foam boards and sheet, the PolyDyne Pro Foam system has a corona electrode that improves the bonding of adhesives and coatings to parts up to 0.4 inch thick. Engineered for use with the company’s PolyDyne Pro generator, the system provides adjustable power and discharge levels for optimum bonding. The unit has a height-adjustable treating head, control panel with HMI and downloadable USB log. Other components include an ozone filter, a tower of status lights and a zero-speed sensor to prevent material damage.

The UltraDyne corona generator is targeted at high-speed decoration of cups and tubes for companies that want to replace old or discontinued corona generators. The unit is designed to maintain consistent, high-quality treatment. The generator can be remotely controlled or linked to decorating line operations.

COROTEC

The company is increasingly focused on automating its systems so they can be in existing treatment lines, as well as inline in production lines.

The company’s new S-Type corona generator offers broader control and interface capabilities than its previous offerings. “A unit’s single HMI interface makes integration, operation and troubleshooting of our corona equipment much easier,” Campbell said. Corona treatment performance is logged in real time, he added, for immediate review or download for quality analysis.

The S-Type power supply includes a 5.7-inch touch screen with data storage and communication capabilities. The unit allows operators to make real-time power adjustments. It displays real-time operational conditions, including trending data that show potential quality problems. It integrates with a production line, upper-level plant tracking system and data storage.

SURFX

Surfx supplies argon plasma treaters for many applications. According to the company, the argon plasma heads produce a uniform beam of a gas at relatively low temperatures. The in-line technology is appropriate for parts, including medical devices, such as catheters, that require gentle treatment.

Sales engineer Kirk Kelly said the company’s most recent developments include its 100mm Linear Beam Plasma Source, a 4-inch treatment head that can be easily added to production lines. The head uses 99 percent argon gas and 1 percent oxygen, nitrogen or hydrogen to remove contaminants from part surfaces. It produces temperatures ranging from 140 degrees Fahrenheit to 248 degrees Fahrenheit.

In addition to handling medical products, which must be manufactured in clean rooms and are subject to strict FDA requirements, the technology is also suited to treating certain types of packaging.

Pat Toensmeier, correspondent

Contact:

3DT LLC,

Germantown, Wis., 262-253-6700, www.3dtllc.com

BTG Labs,

Cincinnati, 513-469-1800, www.btglabs.com

Corotec,

Farmington, Conn., 860-678-0038, www.corotec.com

Enercon Industries,

Menomonee Falls, Wis., 262-255-6070, www.enerconind.com

Surfx Technologies LLC,

Redondo Beach, Calif., 310-558-0770, www.surfxtechnologies.com